Advantages of Molding Plastics for Electronics

Are you searching for innovative solutions in the electronics industry? Look no further! Nolato, a trusted name in the field, provides top-notch plastic molding services tailored specifically for the electronics sector. In this article, we will explore the numerous advantages of molding plastics for electronics, including enhanced design possibilities, advanced customization options, improved durability, and cost-effectiveness.

Enhanced Design Possibilities with Molding Plastics

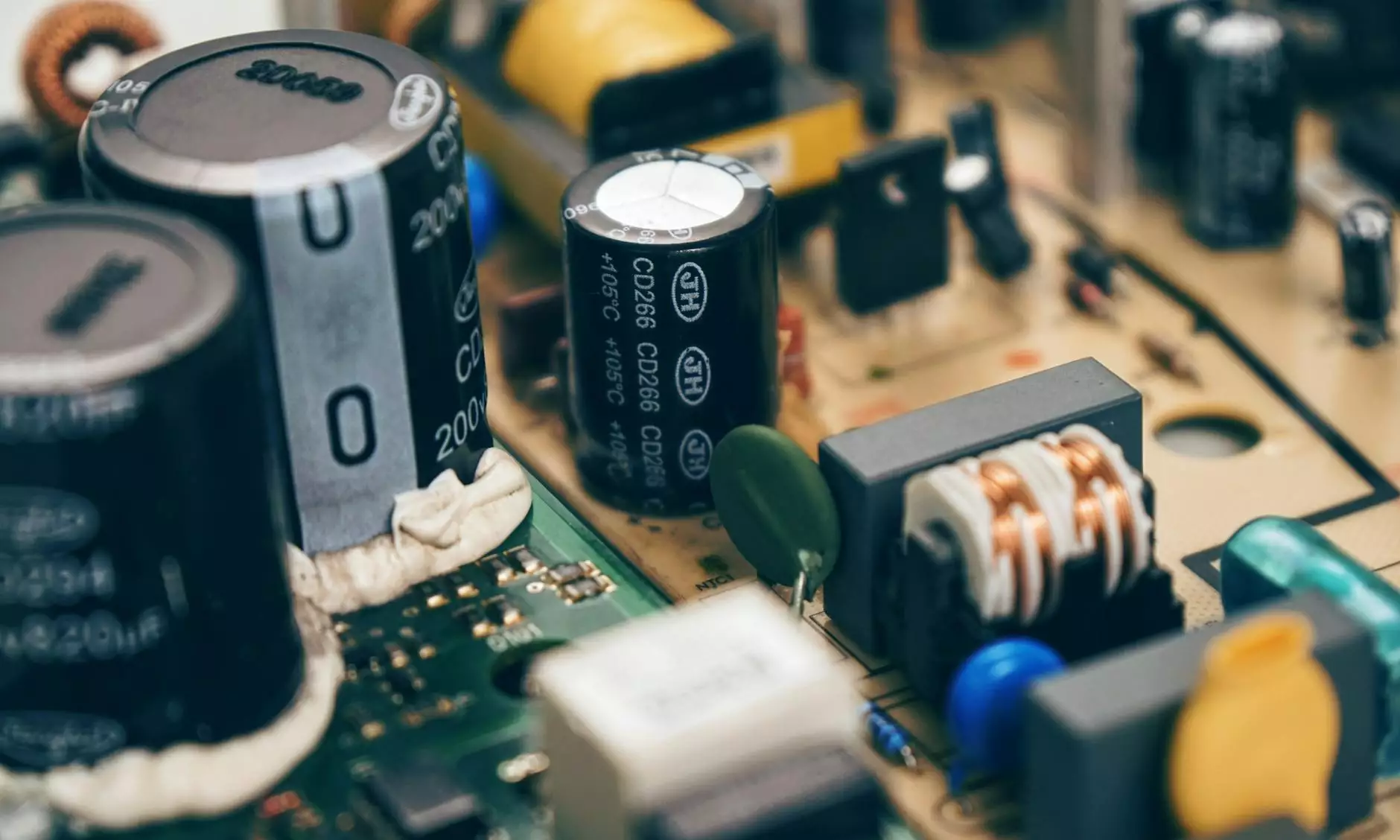

With plastic molding techniques, such as injection molding, companies like Nolato can achieve intricate and complex designs that would be difficult or expensive to produce using other materials or methods. The flexibility of plastics allows for the creation of custom shapes, sizes, and geometries, enabling the realization of even the most demanding electronic device designs.

Moreover, plastic molding provides a smooth and seamless finish, ensuring that the electronics components not only function flawlessly but also look sleek and professional. This aesthetic appeal is crucial in today's competitive market, where consumers and businesses alike are drawn to visually appealing products.

Advanced Customization Options

From color choices to material selection, molding plastics offer a myriad of customization options for electronics manufacturers. With a wide range of plastic materials available, each possessing unique properties, manufacturers can select the most suitable material for their specific electronic device requirements.

Whether the goal is to produce components that are resistant to heat, chemicals, or impact, or to achieve specific electrical or mechanical characteristics, plastic molding affords unparalleled customization possibilities. Nolato, with its expertise in materials science, can assist in selecting the optimal plastic material for your electronic devices, ensuring maximum performance and reliability.

Improved Durability and Performance

Molding plastics for electronics offers inherent advantages in terms of durability and performance. Plastic materials can be engineered to withstand harsh environmental conditions, making them ideal for electronic devices exposed to extreme temperatures, moisture, or vibrations.

Additionally, plastics can provide superior electrical insulation properties, reducing the risk of short circuits and electrical malfunctioning. By choosing the appropriate plastic material and molding techniques, you can significantly increase the lifespan and reliability of your electronics products.

Cost-Effectiveness of Plastic Molding

Cost is a critical consideration for any business, and plastic molding offers notable advantages in terms of affordability. The initial tooling costs for plastic injection molds may require investment, but once the molds are created, subsequent production costs decrease significantly.

Moreover, plastic materials themselves are relatively inexpensive compared to many alternative materials used in electronics manufacturing. Their lightweight nature also contributes to lower transportation costs, making plastics an economically viable choice for businesses.

Additionally, plastic molding enables efficient manufacturing processes with high production rates, reducing overall cycle times and increasing productivity. Through automation and precision engineering, Nolato ensures that your electronic devices are manufactured efficiently without compromising quality or performance.

Conclusion

When it comes to molding plastics for electronics, Nolato stands out as a leading provider with a track record of excellence. The advantages of plastic molding, including enhanced design possibilities, advanced customization options, improved durability, and cost-effectiveness, make it a preferred choice for electronics manufacturers worldwide.

By leveraging the expertise and innovative technologies provided by Nolato, businesses can push the boundaries of electronic device design, optimize performance and reliability, and stay ahead in a competitive market.