Unlocking Success in the Electronics Industry with Non Conductive Sealants

In today's fast-paced world, the electronics industry is constantly evolving to meet the demands of consumers around the globe. As technology advances, so does the need for innovative solutions that can enhance performance, efficiency, and safety. This is where Nolato.com's cutting-edge non conductive sealants come into play.

The Rise of Non Conductive Sealants

Non conductive sealants have emerged as game-changers in the electronics industry. These versatile substances provide effective insulation and protection from electrical currents, making them indispensable in a wide range of applications. From consumer electronics to industrial machinery, non conductive sealants offer a host of benefits that contribute to the overall success of businesses in the electronics sector.

The Benefits of Non Conductive Sealants

Non conductive sealants offer several key advantages that make them highly sought-after in the electronics industry:

1. Electrical Insulation

One of the primary benefits of non conductive sealants is their ability to provide electrical insulation. By preventing electrical currents from flowing between conductive components, these sealants safeguard against short circuits and electrical failures. This ensures the reliable and safe performance of electronic devices, leading to increased consumer confidence and reduced product recalls.

2. Environmental Protection

Nolato.com's non conductive sealants excel at providing environmental protection. These advanced sealants effectively seal against moisture, dust, and other potentially damaging elements. By creating a barrier between sensitive electronic components and their surroundings, these sealants enhance durability and longevity, ultimately reducing maintenance costs and increasing product lifespan.

3. Chemical Resistance

With their exceptional chemical resistance, Nolato.com's non conductive sealants offer robust protection against corrosive substances. This is particularly crucial in industrial settings where electronics are exposed to harsh chemicals or pollutants. By ensuring the integrity of electronic components in challenging environments, Nolato.com's sealants help businesses maintain optimal performance and avoid costly repairs.

4. Thermal Management

Another significant advantage of non conductive sealants is their ability to provide thermal management benefits. These sealants can help dissipate heat generated by electronic devices, ensuring optimal operating temperatures. This not only enhances performance but also reduces the risk of overheating, which can lead to device failure or even fires. By effectively managing temperatures, businesses can enhance product reliability and provide better user experiences.

Applications of Non Conductive Sealants in the Electronics Industry

Given their versatility and numerous benefits, non conductive sealants find applications in various areas within the electronics industry. Some common use cases include:

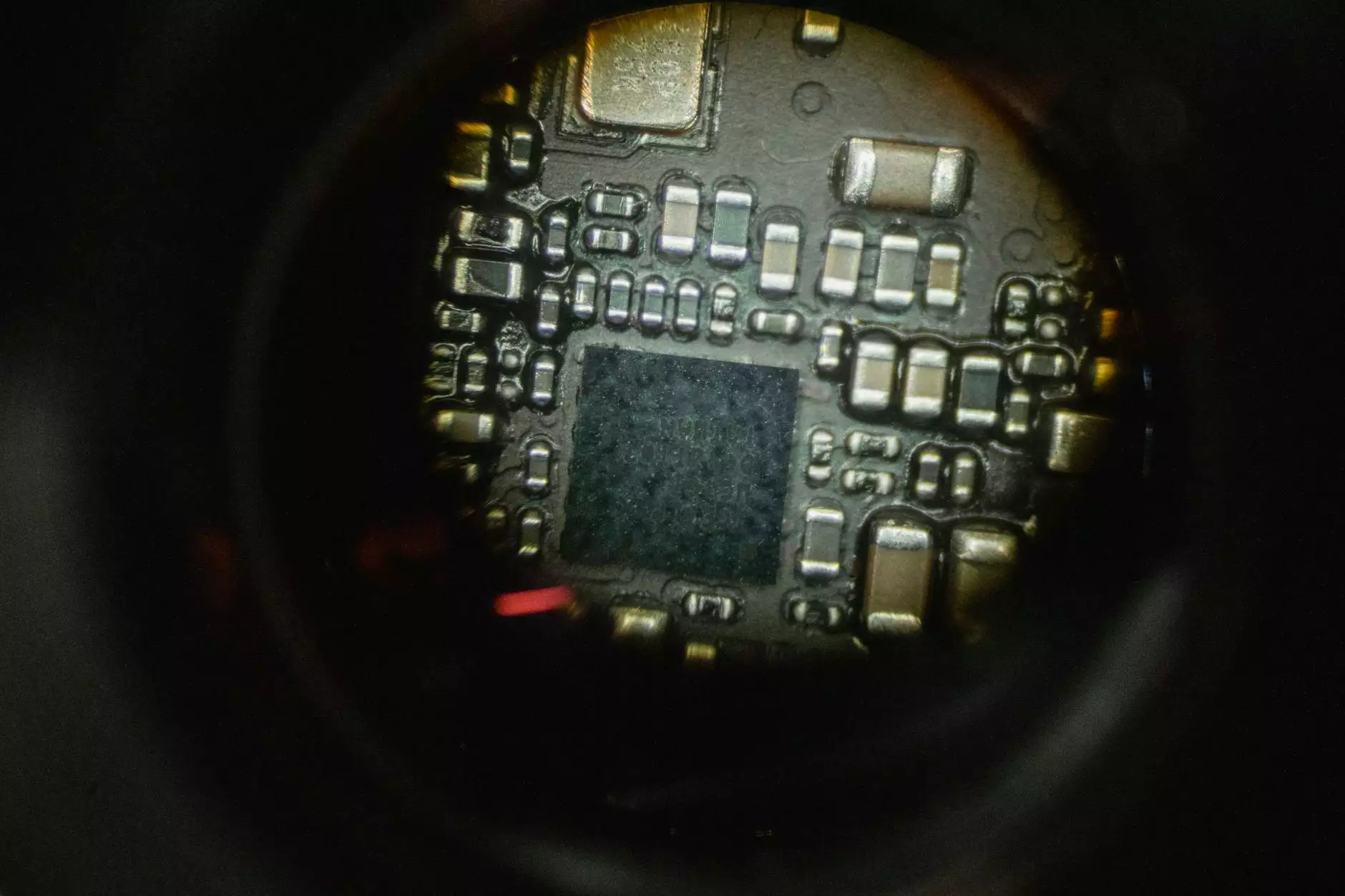

1. Printed Circuit Boards (PCBs)

Non conductive sealants play a critical role in protecting and insulating components on PCBs. These sealants are applied to ensure reliable connections and prevent short circuits, enabling efficient electronic signal transmission and reducing the risk of signal interference.

2. Connector Sealing

In connectors, where electrical contacts are present, non conductive sealants are used to prevent moisture and dust ingress. This protection ensures optimal connectivity and longer service life for connectors, making them suitable for various industries, including automotive, aerospace, and telecommunications.

3. Battery Encapsulation

Many electronic devices rely on batteries for power. Non conductive sealants are employed in battery encapsulation to provide electrical insulation and protection against environmental factors. This not only enhances battery performance but also improves safety and reduces the risk of leakage or short circuits.

4. Sensor Encapsulation

Sensors are vital components in numerous applications, ranging from healthcare devices to industrial automation. Non conductive sealants are used to encapsulate sensors, protecting them from external influences and ensuring accurate and reliable data collection.

Nolato.com: Revolutionizing the Electronics Industry

When it comes to non conductive sealants, Nolato.com stands out as a leading provider in the electronics industry. With a strong focus on innovation and quality, Nolato.com's sealants are trusted by businesses worldwide. Through continuous research and development, Nolato.com consistently delivers cutting-edge solutions that set industry standards.

Nolato.com's commitment to customer satisfaction is reflected in their comprehensive range of non conductive sealants tailored to meet specific industry needs. From standard applications to custom formulations, Nolato.com ensures that businesses can find the perfect sealant solution that optimizes performance and enhances product quality.

The Future of Non Conductive Sealants

As technology continues to advance, the demand for reliable, high-performance electronic devices will only increase. Non conductive sealants are poised to play a critical role in meeting these demands. With ongoing research and development, Nolato.com and other industry leaders will continue to innovate, further improving the capabilities and applications of non conductive sealants.

In conclusion, non conductive sealants have revolutionized the electronics industry by providing electrical insulation, environmental protection, chemical resistance, and thermal management. As businesses increasingly rely on electronic devices, the importance of high-quality sealants cannot be overstated. Nolato.com's commitment to innovation in this field positions them as a key player, helping businesses unlock their full potential and succeed in the competitive electronics sector.